Specialist Machining & Machine Shop Solutions for Custom Industrial Parts

Advanced machining and machine shop solutions are fundamental to the fabrication of custom industrial pieces. These services support numerous industries, ensuring precision and quality in every component. Experienced machinists apply advanced approaches to meet specific project requirements. Understanding the details of these processes can greatly influence product results. As industries evolve, so too do the technologies that drive these solutions. What does this mean for future manufacturing methodologies?

Top Advantages of Custom Machined Parts Across Multiple Industries

While mass-produced components have their place, custom machined parts present notable advantages that can significantly enhance different industries. One of the principal benefits is precision; custom machining facilitates exact specifications tailored to specific applications, guaranteeing maximum performance. This level of accuracy minimizes the likelihood of errors and minimizes the need for adjustments during assembly.

Furthermore, custom machined parts allow for greater material versatility, allowing engineers to pick suitable materials depending on the environmental conditions and performance requirements. This adaptability can significantly enhance the longevity and durability of components.

Additionally, custom solutions can foster innovation, as one-of-a-kind designs can produce superior functionality and efficiency. In sectors such as aerospace, automotive, and medical, where performance is crucial, these benefits become indispensable. Ultimately, the ability to manufacture specialized parts results in increased productivity and competitiveness in multiple industries.

What Is Specialized Machining and Machine Shop Solutions?

Expert machining and machine shop solutions provide an extensive selection of services designed to satisfy the requirements of diverse industries. These offerings encompass a variety of processes, including precision machining, CNC machining, milling, turning, and grinding, allowing for the creation of intricate and precise components. Expert machinists employ advanced technology and equipment to provide precision and productivity in producing custom parts.

In addition, expert machining services commonly include consultation on design, prototyping, and quality assurance, ensuring that the final products satisfy stringent specifications and industry standards. With capabilities to work with a wide array of materials, from metals to plastics, these machine shop solutions cater to sectors such as aerospace, automotive, medical, and energy. By leveraging expertise in machining techniques and industry knowledge, these service providers help organizations achieve their production goals while maintaining excellent outcomes.

Choosing the Right Machining Partner: Key Elements to Consider

Upon selecting the ideal machining partner, what essential factors should be taken into account? Above all, the partner's proficiency and knowledge in the specific industry must be examined. This includes examining their knowledge of specific materials and processes associated with the project. Moreover, the machining capabilities should correspond to project requirements, such as precision, complexity, and volume.

Another crucial element is the quality assurance methods in place. A reputable partner will have rigorous quality control measures to verify that all parts meet industry standards. Customer service and communication are just as crucial, as a collaborative relationship can streamline more efficient project execution.

Lastly, cost-effectiveness must be taken into account, striking a balance between quality with budget limitations. A comprehensive evaluation of prospective partners using these elements can pave the way for a successful collaboration, eventually resulting in high-quality custom parts that fulfill or go beyond expectations.

How New Technologies Are Changing Machining Services

Innovations in technology are markedly transforming machining services, boosting productivity and precision in the production of custom parts. The integration of computer numerical control (CNC) machines allows for automated and highly precise operations, minimizing human error and increasing output consistency. Furthermore, the adoption of additive manufacturing technologies enables complex geometries to be created with minimal waste, thereby promoting sustainability.

Software innovations, like CAD and CAM, allow for better design and simulation processes, permitting engineers to envision and test components ahead of physical production. Moreover, real-time data analytics and IoT connectivity strengthen monitoring and maintenance, contributing to reduced downtime and optimized production schedules.

These technological innovations not only simplify operations but also enable machine shops to address more efficiently to market requirements. As a result, firms can offer tailored solutions while keeping competitive pricing and shorter lead times, ultimately reshaping the landscape of machining services.

Navigating the Process: From Prototype to High-Volume Production

Though converting from prototype to large-scale production can be challenging, a well-defined process can facilitate this journey. Initially, clear specifications and design documentation are vital, making certain that all stakeholders comprehend the project requirements. Next, a thorough evaluation of production capabilities, materials, and technology must be conducted to determine the most effective methods.

Subsequently, a pilot run is frequently carried out to evaluate the manufacturing process, allowing the identification of potential issues before full-scale production starts. During this phase, collaboration between engineers and production teams helps refining techniques for efficiency and quality assurance.

When pilot validation is complete, ramping up production necessitates meticulous planning, involving management of timelines and allocation of resources. Constant monitoring and feedback processes will help copyright quality and accommodate any unpredicted difficulties. By following these steps, businesses can effectively shift from prototypes to complete production, ensuring both efficiency and product integrity.

FAQ

What Types of Materials Work for Custom Machined Parts?

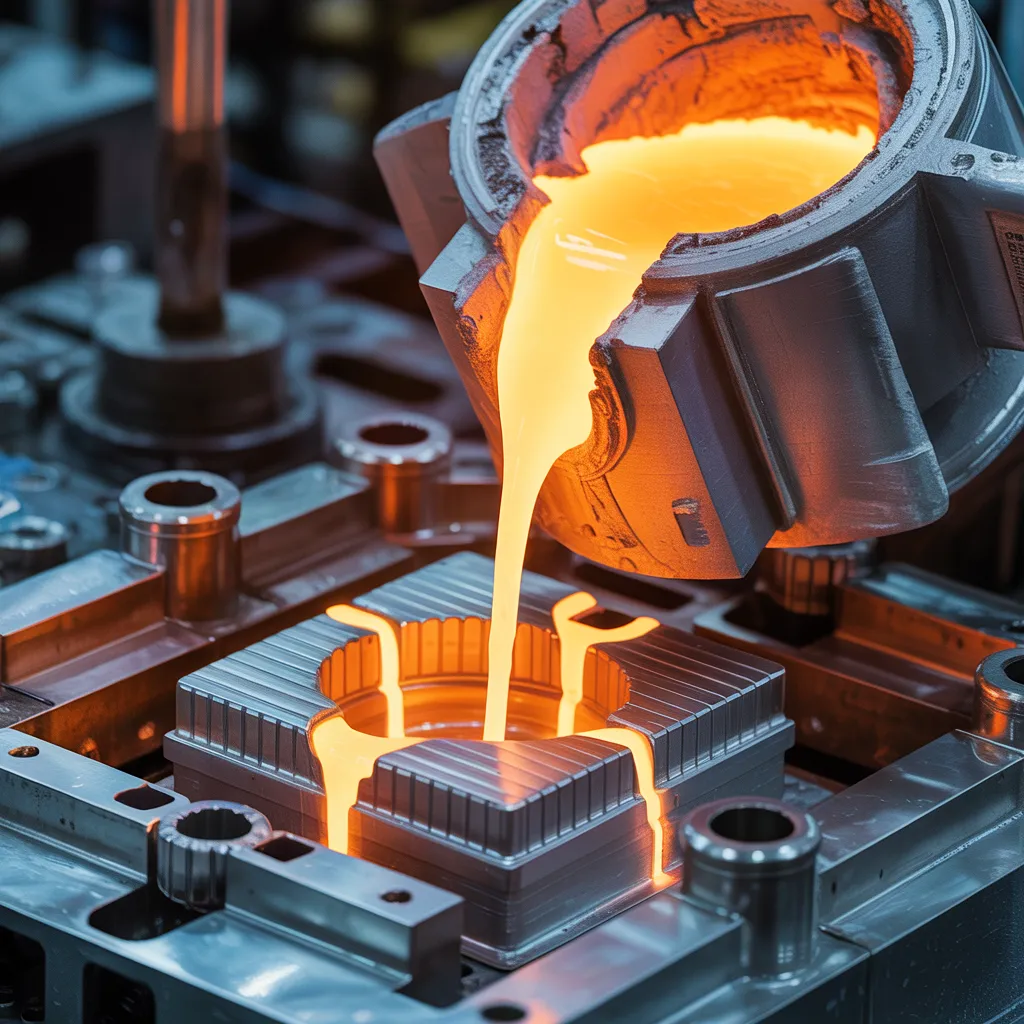

Various materials can be utilized for custom machined parts, including aluminum, steel, titanium, brass, and plastics. The selection depends on elements including strength, weight, aluminum mold corrosion resistance, and the specific application specifications.

How Do I Ensure Design Accuracy in My Specifications?

To maintain design accuracy in specifications, one should use precise measurement tools, create comprehensive drawings, engage in thorough reviews, and collaborate with experienced engineers. Regular feedback and iterative prototyping can also boost overall precision and reliability.

What is the Average Turnaround Time for Custom Machining Projects?

Average turnaround time for custom machining projects differs, typically ranging from several days to multiple weeks. Aspects determining this include project complexity, material availability, and the shop's production load, affecting overall production timelines.

Do Minimum Order Quantities Exist for Custom Machined Parts?

Normally, custom machined parts do have minimum order quantities, which can vary depending on the sophistication, material, and machining processes involved. These stipulations provide effective production and cost-effectiveness for both the manufacturer and the client.

What's the Best Way to Maintain My Custom Machined Parts After Production?

For maintaining custom machined parts after production, regular cleaning, lubrication, and inspection for wear are crucial. Furthermore, storing parts in a controlled environment can avoid corrosion and lengthen their operational lifespan notably.